Back in the day, no professional chef would be seen using anything but a Henkels, Forchner, Wushöf-Trident, Sabatier, or F. Dick 8″ Chef’s Knife. These are made in Germany and France, and were the last word in professional cutlery. I still have my set of Professional S Henkels knives that were presented to me upon graduation from Culinary School.

But times change. Professional-grade knives are now made in the USA, Germany, France, and from the Land of the Rising Sun….Japan. Japanese knives have taken the industry by storm, and their sharpness, and agility are said to be legendary, much as their ancestors, the Katana, and Wakizashi swords of the Samurai. But is it really true, or just hype? If you are looking for the answer to the question, “Should I buy German, or Japanese kitchen knives?”, then read on……

Before making a decision, it is necessary to understand a little about chef’s knives in general. A typical classic European knife will be around 8″ long, with a wide blade, and a strong bolster to give support to the blade for heavy jobs, like cutting frozen meat. The steel will usually be either high carbon, or stainless steel. Some of the best used to be made in Solingen, Germany, arguably the world’s capitol for fine knife steel. Other great steel cities are Sheffield, England, and now, Seki, Japan. High carbon is a ‘softer’ steel that is very durable, holds a good edge, but needs frequent sharpening, and extra care to prevent rust. High carbon steels like AUS-10 have a Rockwell Hardness of around 58. Stainless steel, such as 440C is harder than high-carbon, with a Rockwell Hardness of around 62. They can be made sharper, and hold an edge longer, but are harder to re-sharpen. Japan has gone one step further, with Vanadium Stainless Steel in a layered blade. It is a very hard layer of stainless, sandwiched between two softer, tougher steels. These can be honed to almost a razor edge, and hold that edge very well. They can have a Rockwell Hardness of 64-68. The downside is that they are a lot more work to re-sharpen. Classic European-style knives usually have a full tang, meaning they are made from a single piece of steel that runs all the way to the end of the handle. It was believed that these blades were stronger than other types. In practice however, partial-tang knives are just as tough and durable when made by a good manufacturer.

Let’s take a look at some typical knives:

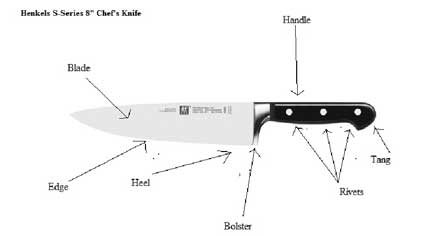

This is my Henkel’s S- Series 8″ Chef’s knife. I have used it for over 25 years, and it is still in like-new shape. Notice the shape of the blade. It has a slight curve (known as ‘belly’) to the edge to facilitate rocking it back and forth when chopping (as we were taught in school). The blade is wide, and thick at the spine to allow it to be used heavily, and even can be whacked with a wood or poly hammer (known as ‘batoning’). The knife is heavy, and feels good in the hand, but due to the bolster, only allows for a standard grip. Classic Euro knives usually have beautiful handles (called ‘scales’) made from exotic woods or micarta. From a cosmetic point of view, this is great, but from a culinary point of view, not so good. Bacteria can hide in wood pores, and get under the handle. One-piece poly handles are much more sanitary. Henkels has been in business since the late 1600s. Most top Euro knife companies have been in business for several hundred years.

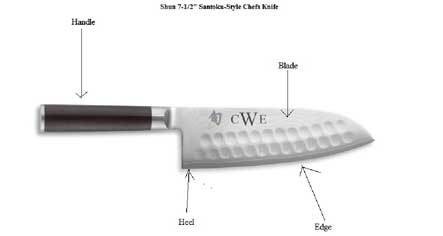

Now, let’s look at a typical Japanese knife. This one is my Shun 7″ Santoku:

The first thing you may notice is that it has no bolster.. And the handle shape is non-ergonomic, meaning it can be held in several different grips comfortably. The blade has little belly, allowing me to dice things so fine as to almost be granular, and is much thinner, especially near the spine. This makes the whole knife lighter, and allows for paper-thin slicing. The steel is a much harder Vanadium Stainless steel, layered between two softer steels. This allows it to take an almost shaving-sharp edge. It is harder to sharpen, but it goes right back to the hair-shaving factory edge. It is light, and very maneuverable, allowing it to be used for decorative cuts. The handle is one-piece micarta, with no spaces for bacteria to hide in. I’ve had this knife for about 5 years, and used it hard. It still looks like new.

German knives are heavy and solid-feeling. They are good for extra tough jobs, like cutting frozen meat, through bones, etc…. They are not as sharp as the Japanese blades, and not as agile, but they will do jobs that may cause a delicate Japanese blade to fail (I have seen Japanese blades ‘chip’). Japanese knives are delicate, light, quick and agile. They are comfortable to use for long times, are much harder and sharper, and able to do more precise cutting.

Ideally, I would recommend having at least one good German, and one good Japanese knife. If I could only have one, I would probably lean towards the Japanese knives for their versatility. As far as price, there is not much difference. They all make knives in the $50.00-$100.00 range, up into the hand-made, custom range of $1000.00 and up. It just depends on what you want.

Now that you know a little more about knives, it may be easier to decide, “Should I buy German, or Japanese kitchen knives?”